Origami is the ancient art of folding paper into delicate, intricate creations. But in University of Illinois labs, origami is also a science. Illinois researchers have found a way to fold microscopically thin slices of silicon into all kinds of useful shapes, which could have applications in many areas, including solar energy.

Specifically, researchers have found an effective, efficient way for silicon to fold itself into three-dimensional spheres, which could be used as solar cells, says Ralph Nuzzo, U of I chemistry professor. A spherical solar cell would be able to absorb the energy of the sun much more efficiently than a typical, flat solar cell.

For greatest efficiency, sunlight needs to hit solar cells from directly above. But with flat cells, this means using motors to move the “big slabs of semiconductor” around to follow the sun as it moves across the sky, Nuzzo explains. Another way the industry handles this problem is with complex optics that redirect the sun’s rays so they always strike the flat surface from above.

A spherical solar cell, in contrast, is a much simpler way to make efficient use of the sun’s rays, trapping light from nearly all directions, he says.

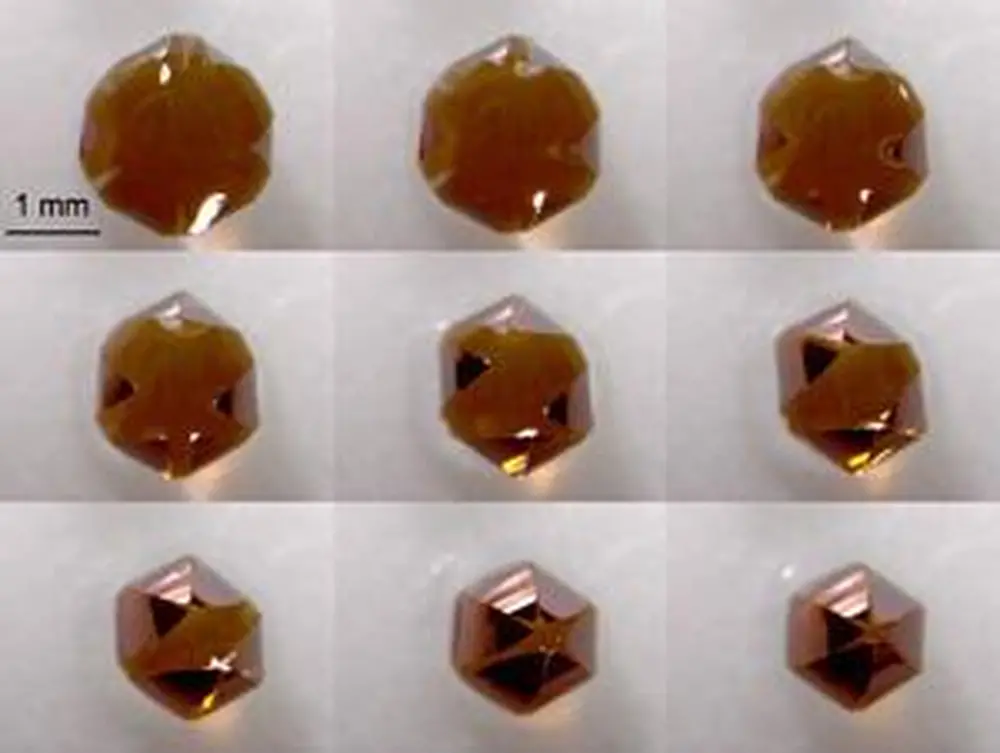

To make a spherical solar cell possible, U of I researchers solved the long-standing problem of how to create three-dimensional shapes out of traditional, single-crystal semiconductor material. They begin with a two-dimensional piece of silicon, cut into the shape of a flower with a small piece of glass imbedded in the center to help the structure maintain its eventual shape. They place a drop of water in the center of the silicon flower; and as the water evaporates, surface tension pulls up the various “petals” of silicon, bringing them together to form the sphere.

The work is in the early stages, but if this system proves to be practical, Nuzzo says compact, spherical solar cells could be wired into large arrays that provide the same power as conventional, flat cells, but using far less silicon. In conventional solar cells today, the thinnest silicon is 300 microns but typically much thicker. The silicon that Nuzzo’s team is using is dramatically thinner—3 microns and less. (Human hair is roughly 40 to 300 microns thick.)

The spherical solar cell work is part of a larger U of I program across many departments—a program that makes new, high-performance devices with unconventional shapes and forms. For instance, John Rogers in chemistry has developed stretchable silicon, opening up the possibility of embedding electronics in flexible materials, such as clothing.

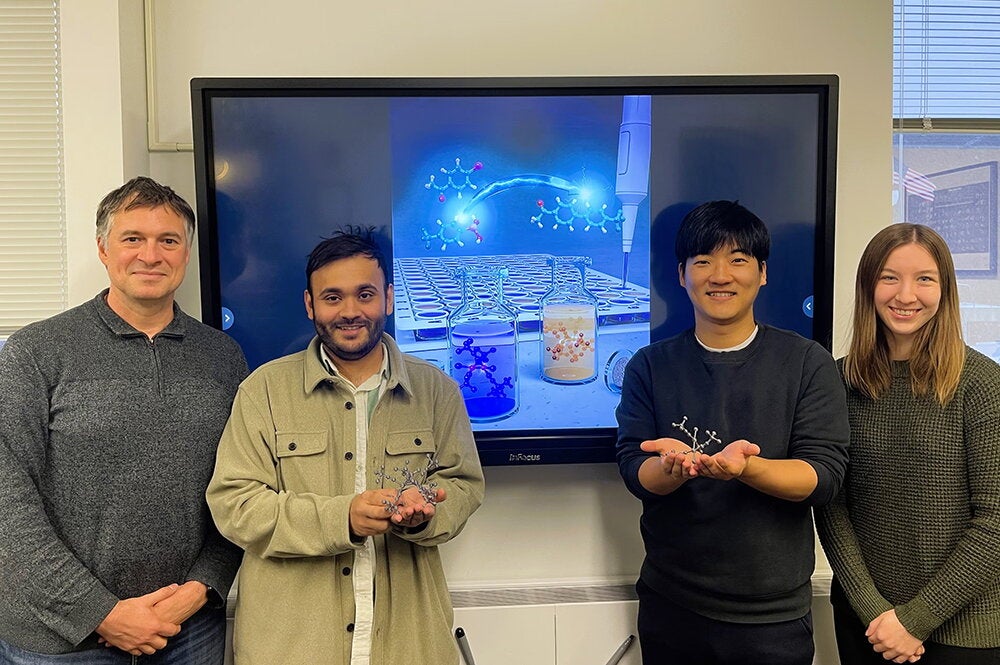

In the spherical solar cell project, Nuzzo and his graduate students work on the materials chemistry, while Jennifer Lewis and Jimmy Hsia, both materials science and engineering researchers, work on the self-assembly folding process. In fact, Hsia and Lewis have found a way to generalize the assembly process so that silicon can fold into many different complicated shapes for all types of uses.

“This is a completely different approach to making three-dimensional structures,” Nuzzo says. “We are opening a new window into what can be done in self-assembly processes.”