Those pesky sulfur compounds in petroleum fuels have met their nano-match.

University of Illinois researchers have developed mats of metal oxide nanofibers that scrub harmful sulfur from petroleum-based fuels much more effectively than traditional materials. Such efficiency could lower costs and improve necessary processes that protect engines and fuel cells.

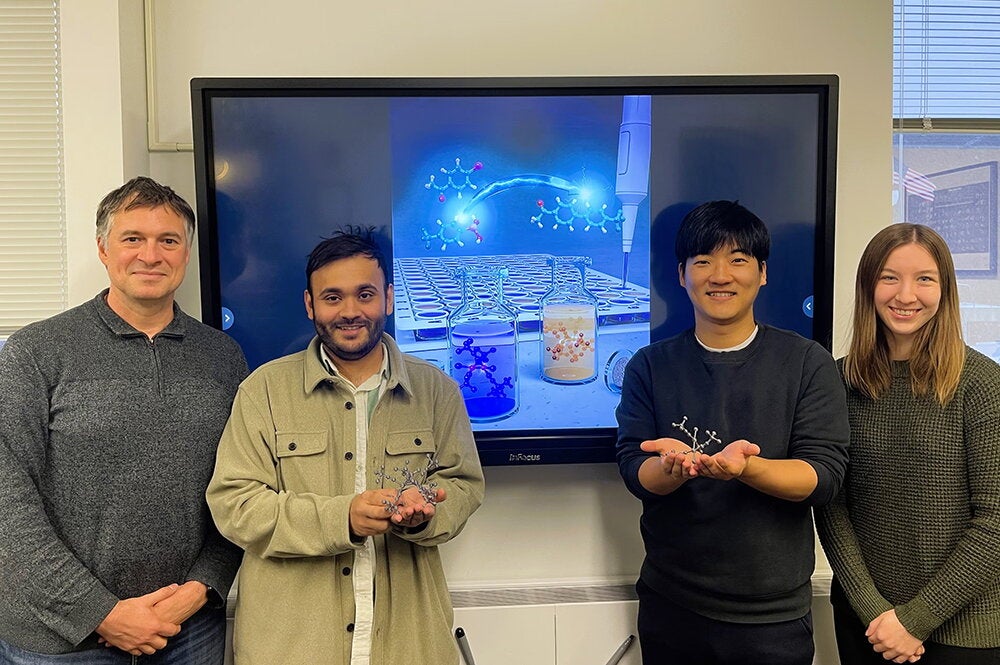

Co-led by chemistry professor Prashant Jain and Mark Shannon, a professor of mechanical science and engineering at the U of I until his death this fall, the researchers demonstrated their material in the journal Nature Nanotechnology.

Sulfur compounds in fuels release toxic gases during combustion, and they damage metals and catalysts in engines and fuel cells. They usually are removed through a cumbersome process using a liquid treatment that adsorbs the sulfur from the fuel, requiring that the fuel be cooled and reheated, making the fuel less energy efficient.

To solve these problems, researchers have turned to solid metal oxide adsorbents, but those have their own sets of challenges. While they work at high temperatures, eliminating the need to cool and reheat the fuel, their performance is limited by stability issues. They lose their activity after only a few cycles of use.

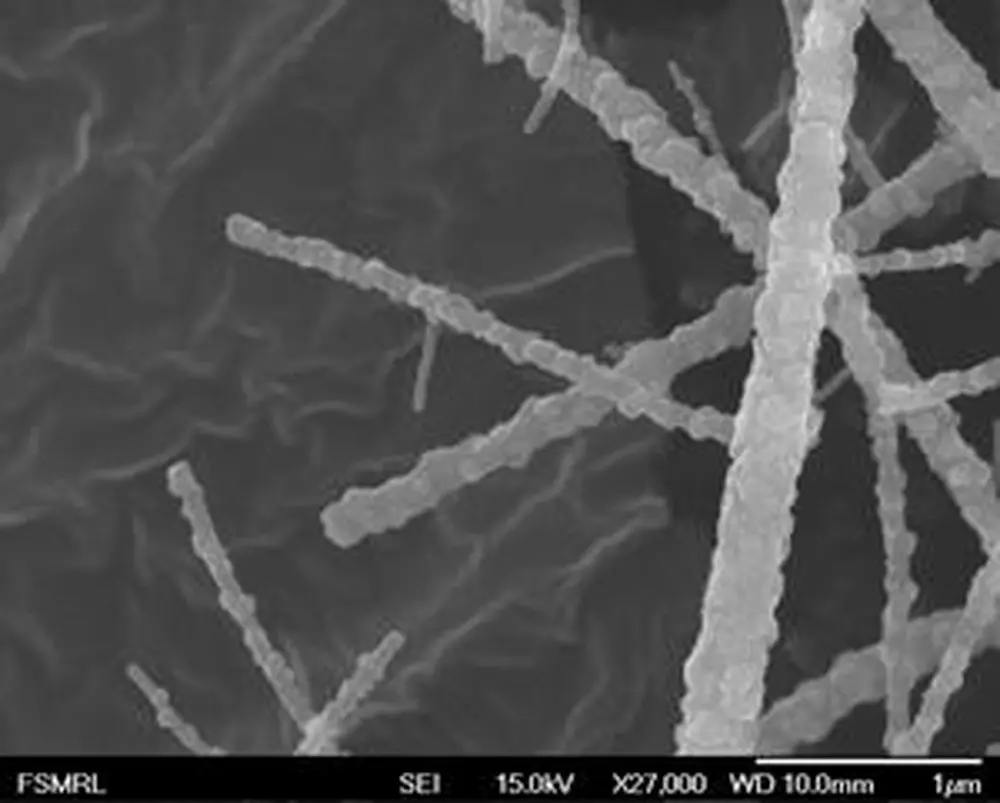

Ultimately, the research team’s solution has been tiny grains of zinc titanate spun into nanofibers, uniting high surface area, high reactivity, and structural integrity in a high-performance sulfur adsorbent.

The nanofiber material is more reactive than the same material in bulk form, enabling complete sulfur removal with less material, allowing for a smaller reactor. The material stays stable and active after several cycles. Furthermore, the fibrous structure grants the material immunity from the problem of sintering, or clumping, that plagues other nano-structured catalysts.

“Our nanostructured fibers do not sinter,” says Jain, who is also affiliated with the Beckman Institute for Advanced Science and Technology at the U of I. “The fibrous structure accommodates any thermophysical changes without resulting in any degradation of the material. In fact, under operating conditions, nanobranches grow from the parent fibers, enhancing the surface area during operation.”

Jain’s group will continue to investigate the enhanced properties of nanofiber structures, hoping to gain an atomic-level understanding of what makes the material so effective.