Understanding how soft materials fail under stress is critical for solving engineering challenges as disparate as pharmaceutical technology and landslide prevention. A new study linking a spectrum of soft material behaviors — previously thought to be unrelated — led researchers to identify a new parameter they call the brittility factor, which allows them to simplify soft material failure behavior. This will ultimately help engineers design better materials that meet future challenges.

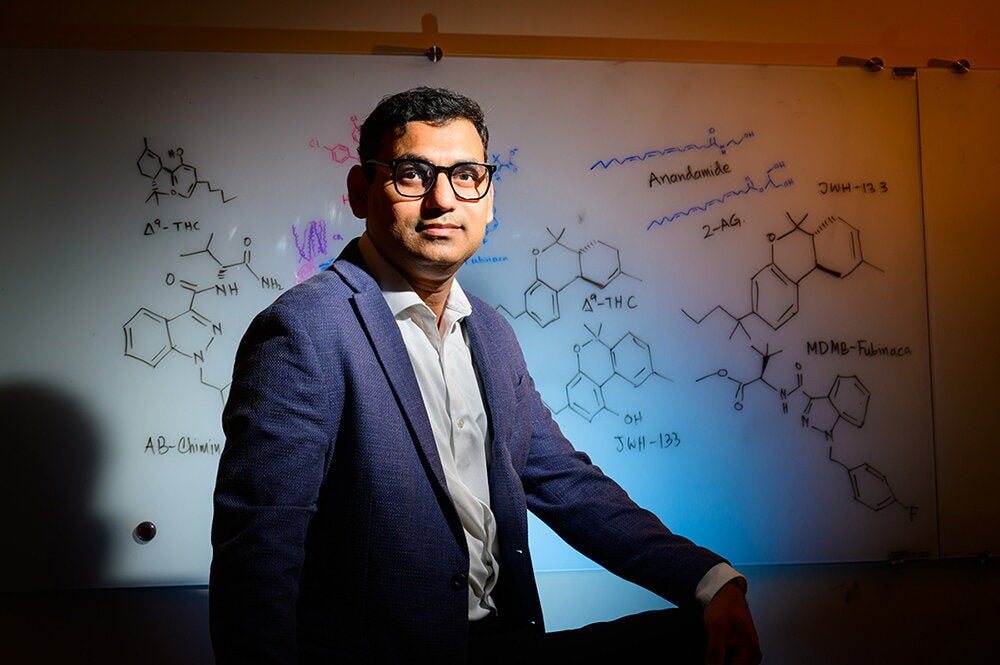

University of Illinois Urbana-Champaign chemical and biomolecular engineering professor Simon Rogers and graduate student Krutarth Kamani specialize in determining how soft materials yield to stress and have shown how solid and liquid physical states can exist together in the same material. This area is of high interest due to its importance to industrial, environmental and biomedical applications.

Along the way, the team identified a communication breakdown among the scientists who work in this area, causing a bottleneck between a theoretical understanding of soft material behavior and real-world applications.

When soft materials — natural or synthetic — deform under pressure, they eventually reach a critical point where they either return to their original form or undergo permanent deformation, like stretching or breaking a piece of elastic. This process is known as yielding. A gradual yielding transition is termed ductile behavior, while an abrupt one is referred to as brittle behavior, the researchers said.

“At a recent conference, we realized that all of us who study soft materials from all over Europe and North America couldn’t agree what the connection is between brittle and ductile behavior nor how to define it.”

In the study, published in the Proceedings of the National Academy of Sciences, instead of viewing soft material behavior as one or the other — brittle or ductile — Rogers’ team considers a spectrum of yielding behaviors. This allowed the team to build a continuum model, which led to them uncovering the brittility factor. This factor is critical in determining how and why soft materials fail.

Essentially, brittility affects how a material deforms permanently under stress. The team’s model indicates that the higher the brittility factor, the less a soft material will deform permanently before yielding.

As in the team’s past studies, the model was developed and tested using data from numerous experiments that subjected various soft materials to stress while measuring the individual strain responses using a device called a rheometer.

“We didn’t expect this study to explain as much as it does,” said Rogers, who is also an affiliate at the Beckman Institute for Advanced Science and Technology at the U of. I. “What we ended up with was a way to bring a whole bunch of soft material behaviors together under the same physics umbrella. Previously, they’d been studied independently or maybe all been applied simultaneously, but never thought of as being physically or mathematically connected.”

This finding will allow researchers to explain precisely why some materials are more resistant to rapid yielding than others, a question that has eluded researchers for decades.

“This single parameter amazingly connects so many puzzling observations researchers have come across over the years,” Kamani said.

“This work marks the point at which we are approaching the crest of the hill in understanding soft materials behavior,” Rogers said. “We’ve always felt like each step takes us higher, but with no end in sight. Now we can see the top of the hill, and we are closer to the top and free to move forward in whatever direction we would like.”

The National Science Foundation supported this research.