Scientists from the University of Illinois Urbana-Champaign, University of California, Santa Barbara, and Dow have developed a breakthrough process to transform the most widely produced plastic — polyethylene (PE) — into the second-most widely produced plastic, polypropylene (PP), which could reduce greenhouse gas emissions (GHG).

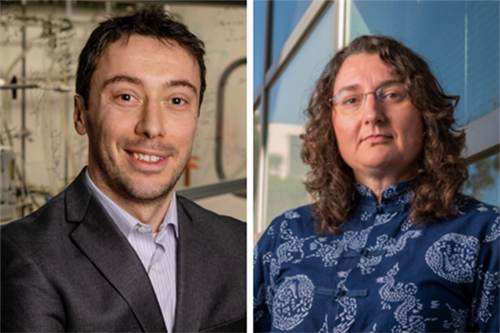

“The world needs more and better options for extracting the energy and molecular value from its waste plastics,” said co-lead author Susannah Scott, Distinguished Professor and Mellichamp Chair of Sustainable Catalytic Processing at UC Santa Barbara. Conventional plastic recycling methods result in low-value plastic molecules and, thus, offer little incentive to recycle the mountains of plastic waste that have accumulated over the past several decades. But, Scott added, “turning polyethylene into propylene, which can then be used to make a new polymer, is how we start to build a circular economy for plastics.”

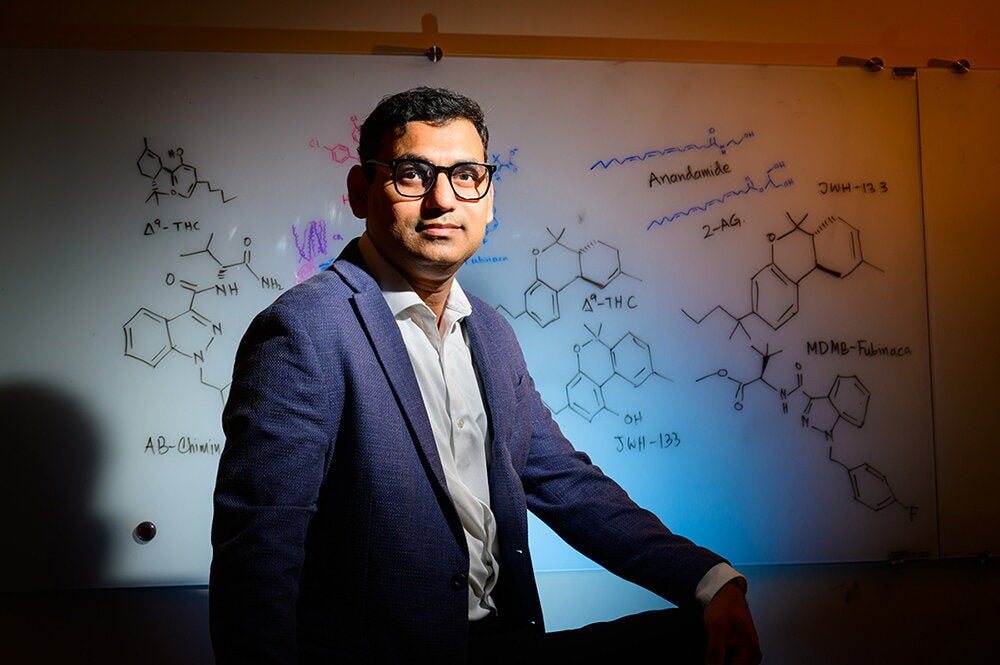

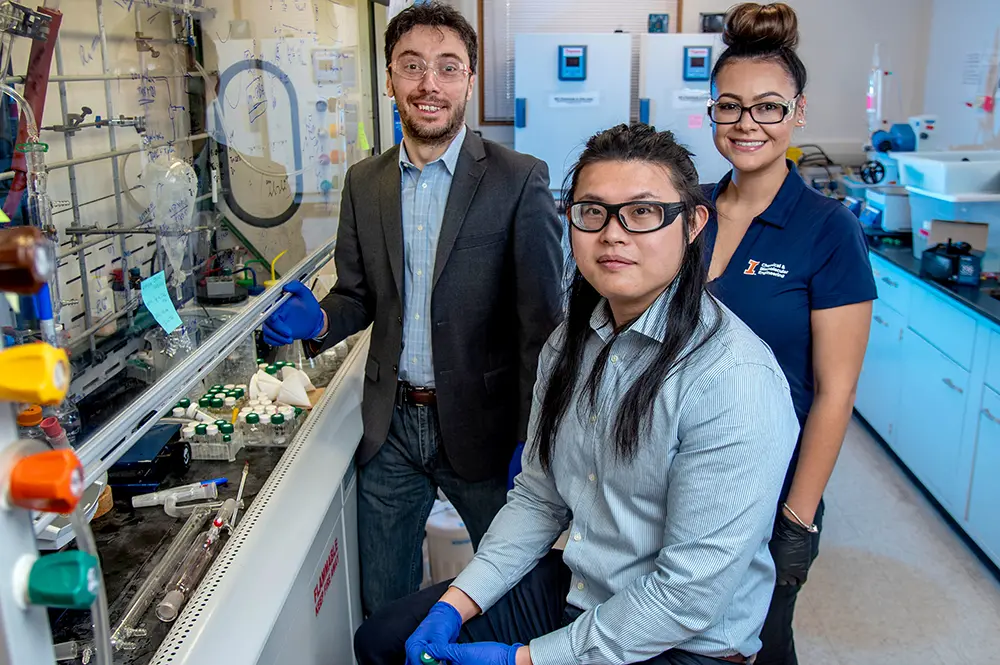

“We started by conceptualizing this approach and demonstrated its promise first through theoretical modeling — now we have proved that it can be done experimentally in a way that is scalable and potentially applicable to current industry demands,” said co-lead author Damien Guironnet, a professor of chemical and biomolecular engineering at Illinois, who published the first study outlining the necessary catalytic reactions in 2020 with chemical and biomolecular engineering William H. and Janet G. Lycan Professor Baron Peters.

The new study published in the Journal of the American Chemical Society announces a series of coupled catalytic reactions that transform PE, which is #2 and #4 plastic that make up 29 percent of the world’s plastic consumption, into the building block propylene that is the key ingredient to produce PP, also known as #5 plastic that accounts for close to 25 percent of the world’s plastic consumption.

This study establishes a proof-of-concept for upcycling PE plastic with more than 95 percent selectivity into propylene. The researchers have built a reactor that creates a continuous flow of propylene that can be converted into PP easily using current technology — making this discovery scalable and rapidly implementable.

“Our preliminary analysis suggests that if just 20 percent of the world’s PE could be recovered and converted via this route, it could represent a potential savings of GHG emissions comparable to taking 3 million cars off the road," said Garrett Strong, a graduate student associated with the project.